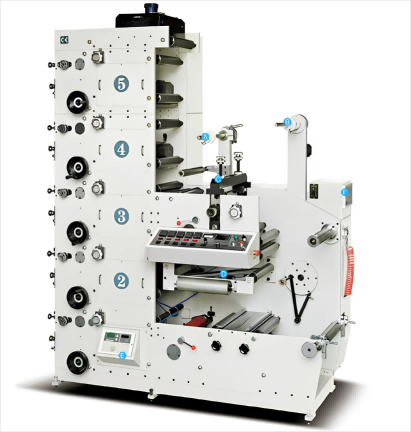

4 color economic CI flexo printing machine has the characteristics of a CI printing machine and can print a variety of materials. At the same time, its maximum speed reaches 150 meters per minute. The printing unit of the CI flexographic printing machine is surrounded by a large Central drum, like a small satellite surrounding a large star. For buyers who want higher printing quality but cannot afford expensive high-speed CI flexo printing machines, it is an economical and cheap choice.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | YTCI4-800E | YTCI4-1000E | YTCI4-1200E | YTCI4-1400E |

| Max. Web Width | 800mm | 1000mm | 1200mm | 1400mm |

| Max. Printing Width | 760mm | 960mm | 1160mm | 1360mm |

| Max. Machine Speed | 180m/min | |||

| Printing Speed | 150m/min | |||

| Max. Unwind/Rewind Dia. | φ1000mm | |||

| Machine structure | Gear drive. | |||

| Thickness of flexo plate & double side tape | Photopolymer plate (2.38+0.38) mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink & solvent ink | |||

| Printing repeat length | 350mm-900mm | |||

| Suitable Material | Plastic film, Paper, non-woven/pp woven and so on | |||

| Machine Voltage | Voltage 380V/3Phase/50 HZ. (or according to customer requirements) | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine Features

◊ A wide range of substrates, such as pet, Bopp, paper, non-woven, pp woven Paper (20-350g/㎡)and so on.

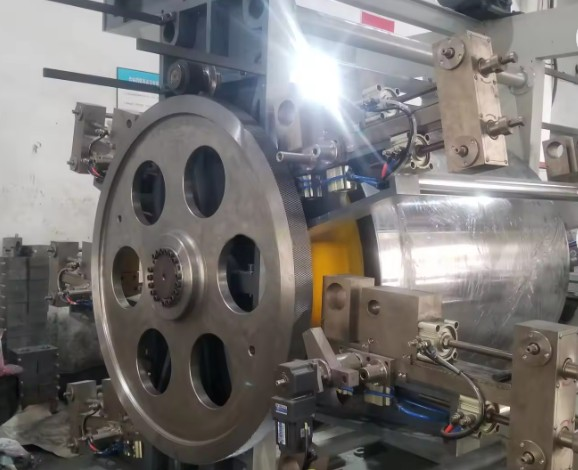

◊ The printing material is tightly attached to the surface of the large central drum, and the tension is stable, especially when printing shrinkable films.

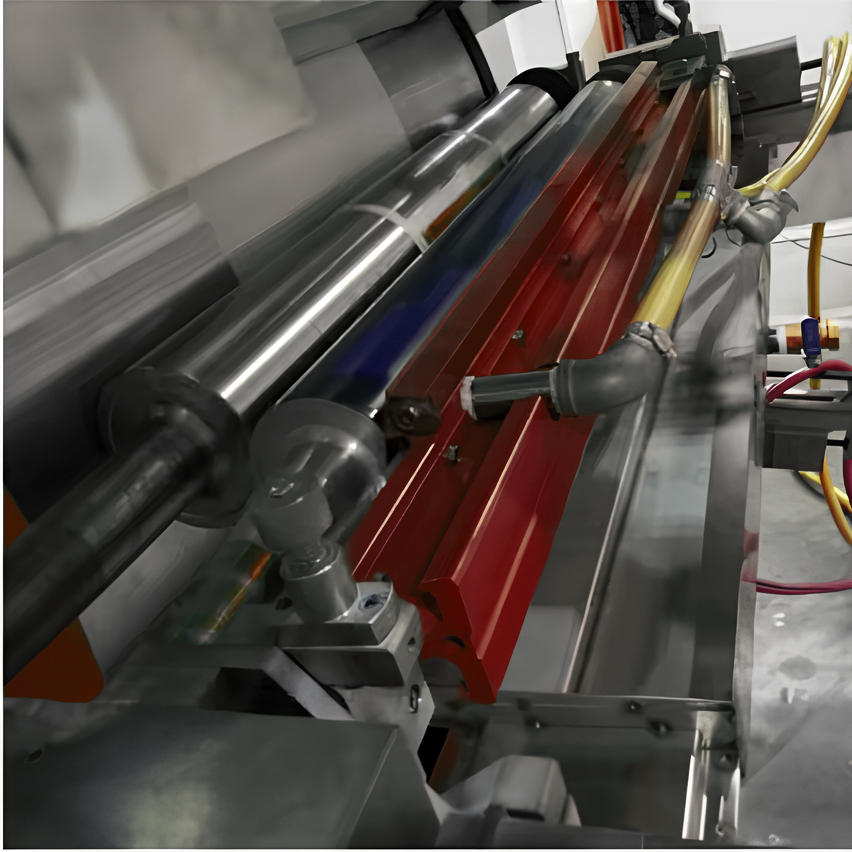

◊ Chamber doctor blade and ceramic anilox roller transfer ink, diaphragm pump circulate ink, ink volume is stable.

◊ The surface of the central impression drum is chrome-plated, with a diameter of up to 2 meters and constant temperature control.

◊ When printing materials such as heat shrink film that require water cooling, a water-cooling device can be installed.

◊ Independent hot air electric heating drying unit, high efficiency and energy saving, optional steam or hot oil drying.

◊ The printing speed can reach up to 200 meters per minute. It adopts electric color registration and pressure adjustment, and the accuracy can reach ±0.12mm.

◊ Machine equipped with a video inspection camera to observe the printing quality in real time.

◊ Computerized automatic color registration systems, UV drying, turn bur, Non-stop roll change platform) can be installed according to customer needs to meet different production needs.

◊ Hydraulic shaft less unwind is optional for customer, unwind part and rewind part can customize according to customer requirements.

Machine Details

Printing Sample

Packaging and Delivery