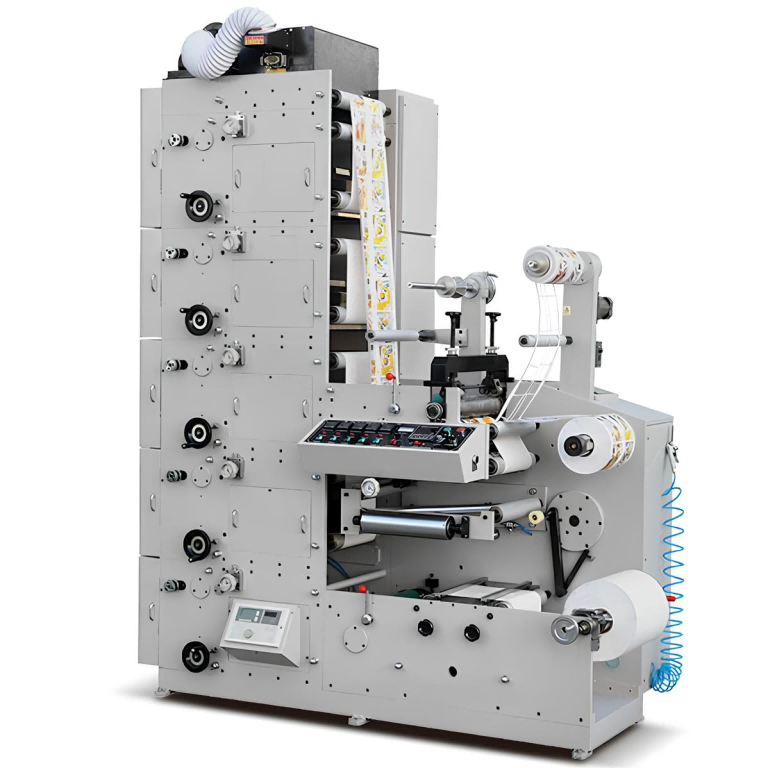

8 color stack flexo printing machine is designed for plastic film material, its max printing speed reach 100meter/min. Double unwind and double rewind, chamber doctor blade and ceramic anilox roller transfer ink, ink pump circulate ink. color registration accuracy reach ±0.15mm, although its printing quality can't compare to CI flexo printing machine, but it is cheaper. It is an economic flexo printing machine.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | GYT8-800 | GYT8-1000 | GYT8-1200 | GYT8-1400 |

| Max. Web Width | 800mm | 1000mm | 1200mm | 1400mm |

| Max. Printing Width | 760mm | 960mm | 1160mm | 1360mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ600mm | |||

| Machine Transmission Structure | Gear drive. | |||

| Plate thickness & doble side tape | Photopolymer plate (1.7+0.38)mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink & solvent ink | |||

| Printing repeat length | 230mm-1200mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET, Plastic Film | |||

| Machine Voltage | Voltage 380V./3Phase/50 HZ. (or according to customer requirements) | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine Features

◊ The whole machine adopts Siemens PLC control and Schneider low-voltage electrical appliances, which is easy to maintain and has a long service life.

◊ Double unwind and double rewind, fast material change,3inch air shaft clamp the material

◊ The unwinding part is equipped with a magnetic powder brake and an automatic tension control system to ensure stable substrate tension.

◊ The unwinding part is equipped with an auto web guide system, and the substrate runs in a straight line.

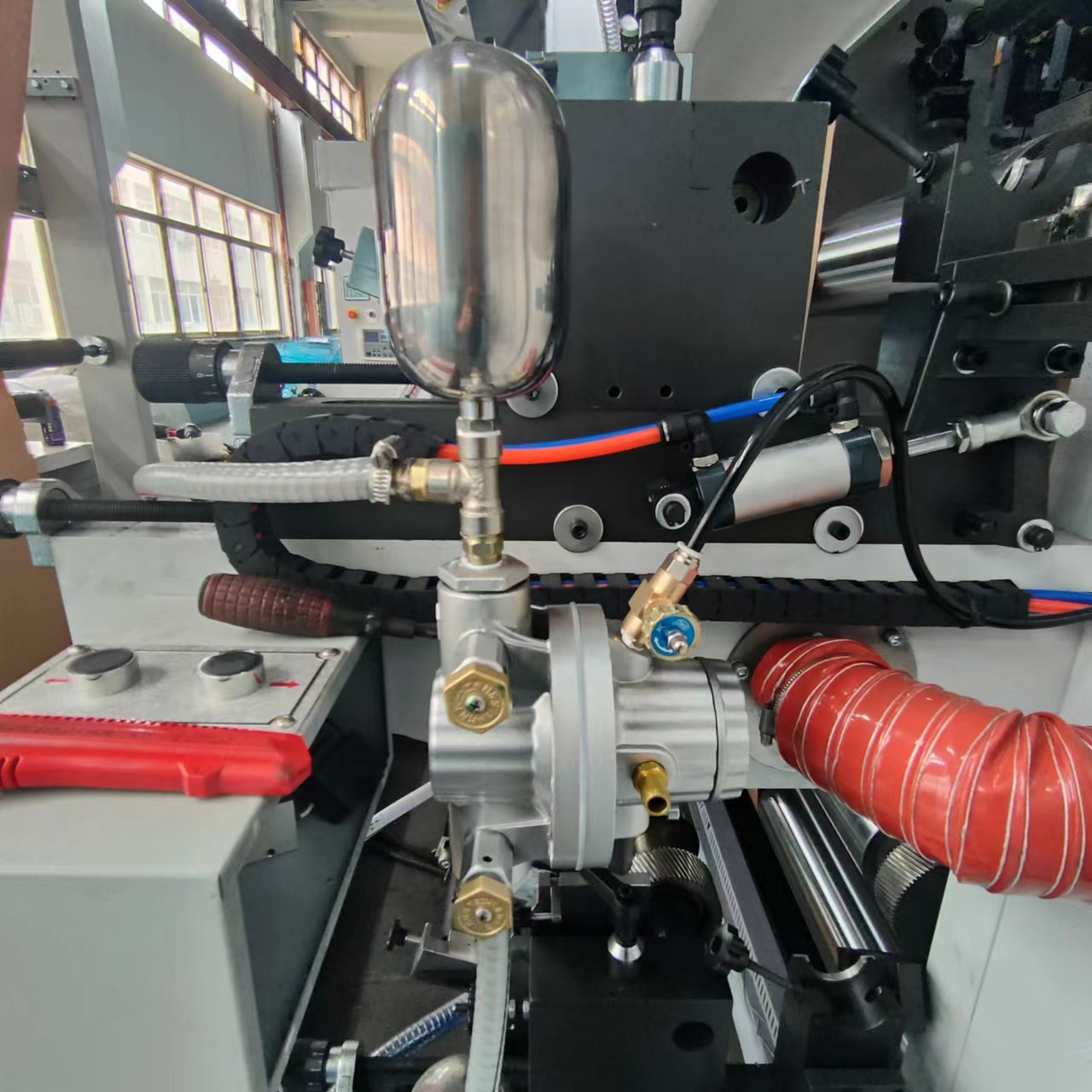

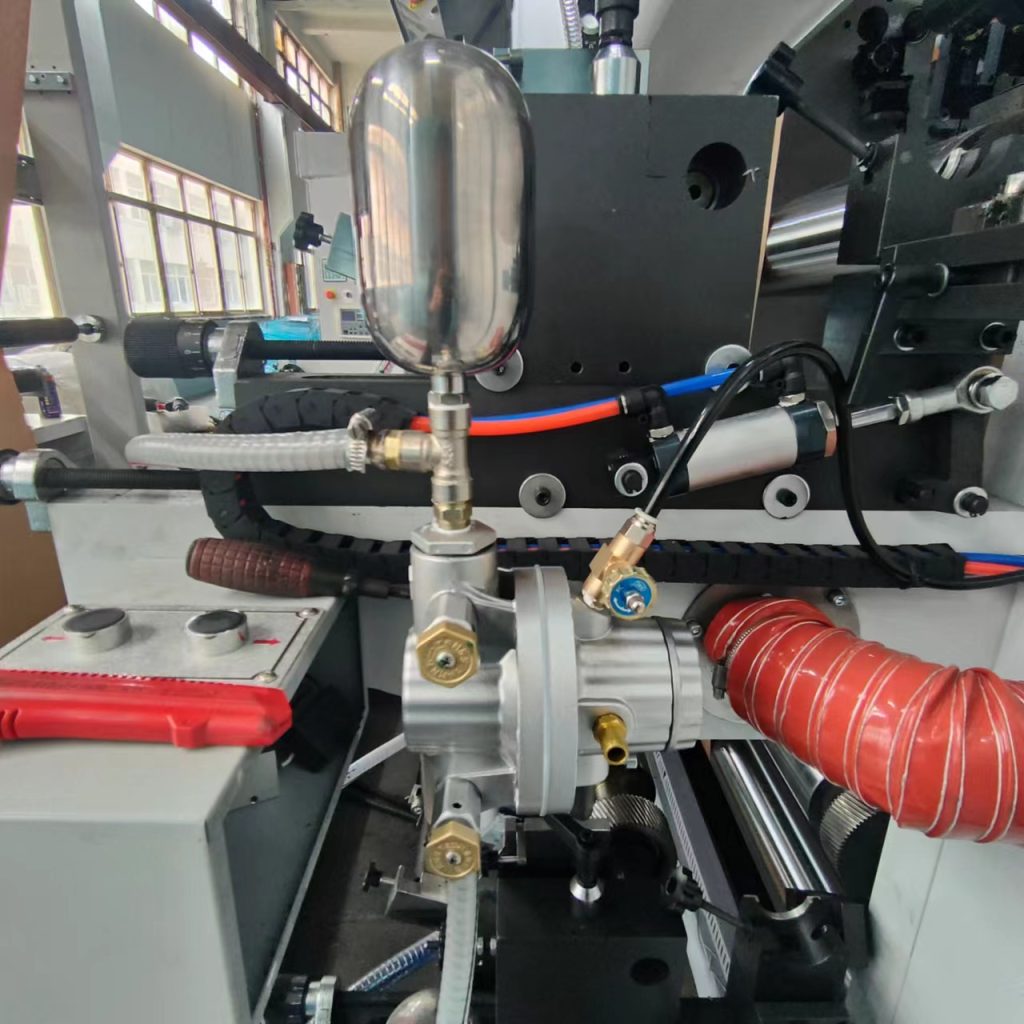

◊ Chamber doctor blade and ceramic anilox roller transfer ink, ink pump circulate ink, ink volume is stable.

◊ Each group of printing units is equipped with a set of small ovens. After printing is completed, it enters the top oven for centralized drying. Electric heating is efficient and energy-saving.

◊ Electric color registration, color registration accuracy can reach ±0.15mm.

◊ When the machine is stopped, the ink transport motor drives the anilox roller to rotate at low speed to prevent the ink from drying out.

Machine Details

Printing Sample

Packaging and Delivery