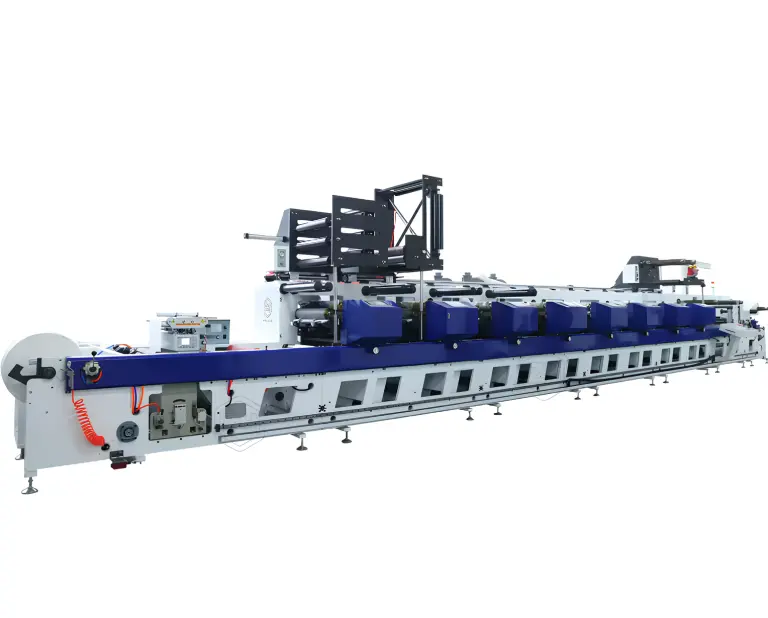

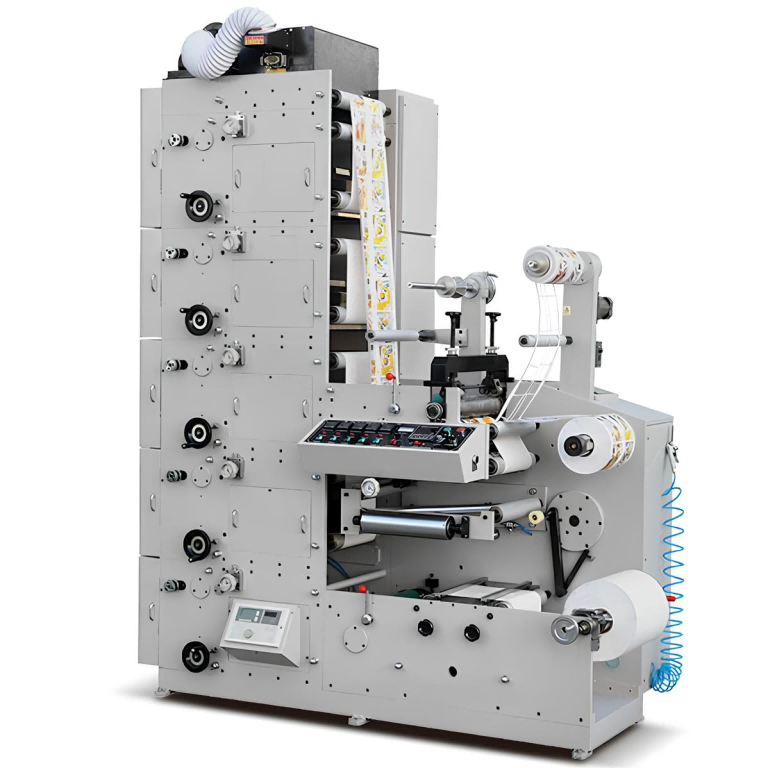

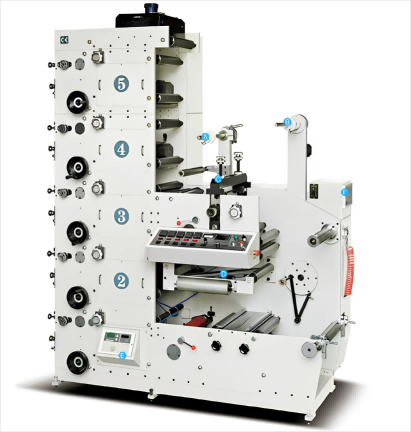

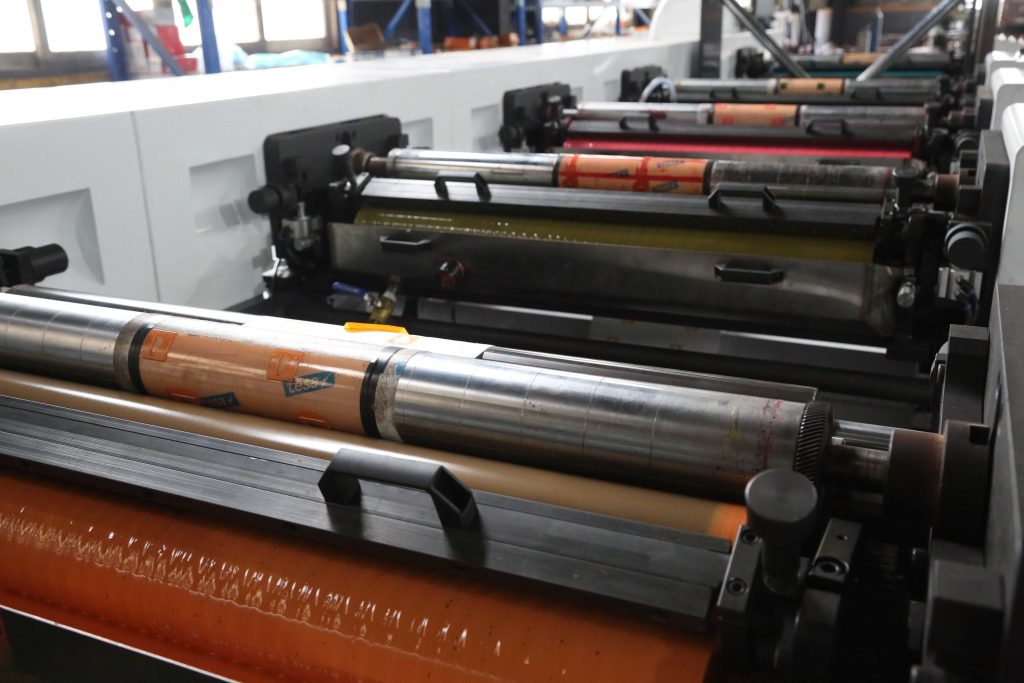

8 colors inline flexo printing machine is an ideal printing machine for all kind of paper/ pre-printing corrugated box/ non-woven bag and pp woven sack. Its max printing speed reach 250meter/min, each printing unit drive directly by servo motor, automatic color registration system, Online quality inspection system, color registration accuracy reach±0.1mm. Hydraulic shaftless unwinding, max unwind diameter reach 1500mm.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | YTB8-800 | YTB8-1000 | YTB8-1200 | YTB8-1400 |

| Max. Material Width | 800mm | 1000mm | 1200mm | 1400mm |

| Max. Printing Width | 760mm | 960mm | 1160mm | 1360mm |

| Max. Machine Speed | 300m/min | |||

| Max. Printing Speed | 150m/min or 250m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm or 1500mm | |||

| Machine Transmission structure | Gear drive or servo motor drive. | |||

| Thickness of flexo plate & double side tape | Photopolymer plate (2.38+0.38mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink & solvent ink | |||

| Printing repeat length | 300mm-850mm | |||

| Suitable Material | PAPER, NON-WOVEN, PP WOVEN SACK | |||

| Machine Voltage | Voltage 380V/Phase/50HZ or according to customer requirements | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine Features

◊ Each group of printing units is equipped with an independent drying oven, which is electrically heated for drying, with fast drying speed and good drying quality

◊ The vertical and horizontal color registration is automatic adjust, The machine is equipped with an automatic color registration system and an online quality inspection system, and the printing accuracy can reach ±0.1mm.

◊ A flip frame can be installed according to customer needs to achieve double-sided printing, as well as optional functions such as non-stop material change and UV drying..

◊ The rewinding uses an air shaft to clamp the material, friction rewinding, and the tension is controlled by a high-precision air pressure valve

Machine Details

Printing Sample

Packaging and Delivery