Des produits de haute qualité, superbe technologie

LES PRODUITS CHAUDS

Lire PlusÀ PROPOS DE NOTRE SOCIÉTÉ

À PROPOS DE NOUS

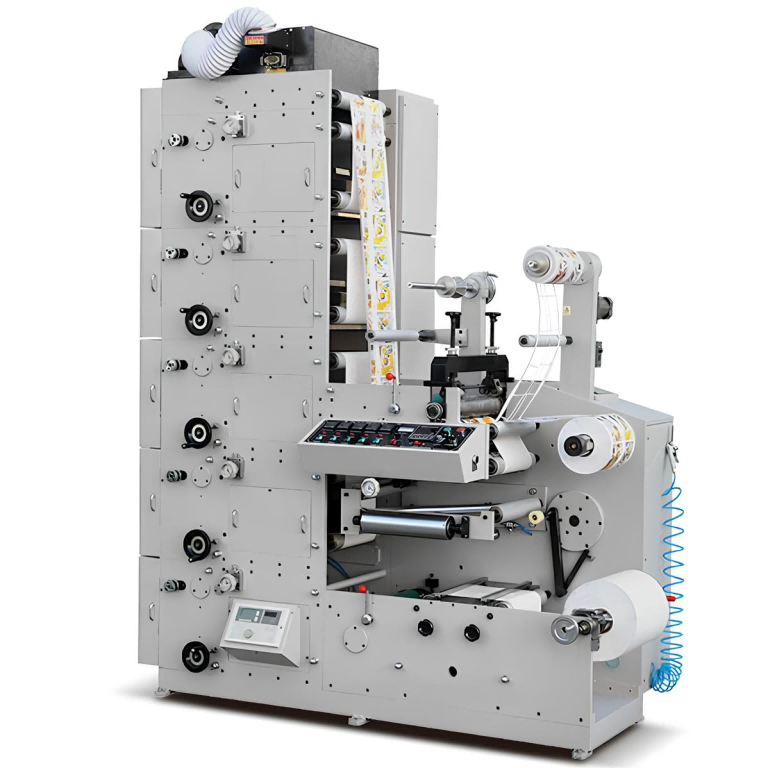

- CI Machine d'Impression Flexo

- Pile de la machine d'impression Flexo

- L'étiquette de la Machine d'impression Flexo

Nous pouvons fournir le meilleur service pour nos clients

Dernières Nouvelles

Comprenez rapidement l’impression flexographique en trois minutes.

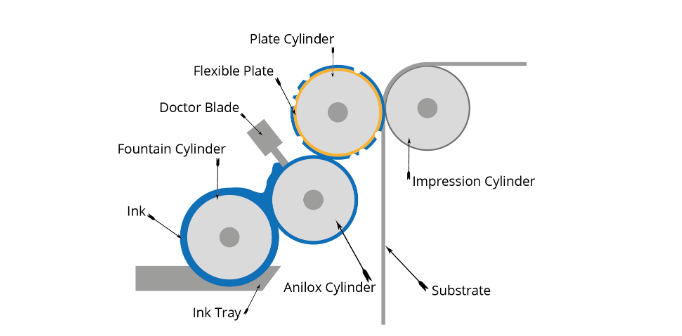

Flexography (flexography), also often referred to as flexographic printing, is a printing method that uses a flexographic plate to transfer ink through an anilox roller. For flexographic printing, the printing plate generally uses a photosensitive resin plate with a thickness of 1-5mm. Inks are divided into three categories, namely water-based ink, alcohol-soluble ink, and UV ink. Since the inks used in flexographic printing are environmentally friendly, they have been widely used in food packaging printing and have broad prospects. Flexographic printing is a type of relief printing. Application Flexographic printing, offset printing, gravure printing and screen printing are the four most common printing methods in the world, each with its own characteristics and advantages. In countries with developed printing industries such as Europe and the United States, flexographic printing has developed rapidly. Packaging printing has changed from gravure printing and offset printing to flexographic printing. About 70% of packaging materials use flexographic printing. Characteristic Compared with gravure printing, offset printing and traditional relief printing, flexographic printing has its own distinctive characteristics: 1. Low cost. Compared with gravure printing machines and corresponding offset printing machines with the same color group, the price of flexographic printing machines is much lower. In addition, the flexographic printing machine integrates printing, die-cutting, glazing and other processes into one. Multiple processes can be completed at one time, eliminating the need to purchase corresponding post-processing equipment, and has a high return on investment. 2. The equipment is simple. The equipment structure is relatively simple, so the operation is relatively simple and convenient. 3. High efficiency. Flexographic […]

Lire Plus

Quelle est la différence entre les 3 types de presse flexographique?

The flexographic printing technique, which is an example of a convex direct printing, is crucial for the printing of plastics. Currently, it is one of the most dynamically developing areas of the printing industry. This is due to the possibility of the widespread use of this technique for printing on both absorbent and nonabsorbent bases. 3 Types of Printing Presses for Flexo Printing There are three main press design types for flexographic printing: 1. Central impression flexo press 2.In-line flexo press 3.Stack flexo press. 1. Stack flexo press Stack type flexo printing machine presses are those where the printing units are stacked one a top another. The individual impression drums located at each station are called impression rolls, whereas the central impression drum (CI-Press) is referred to as the impression drum. The main press frame consists of several individual colour stations (sometimes sections or decks). These stations are driven either by gear trains supported by the press frame or servo motors. The most common configuration for stack presses is a Six-color press; however, stack presses can have from one to eight colour stations. It is possible to print on both sides of a substrate using a stack press. Small runs can also be printed on the stack press. Five advantages of stack type flexo printing machine: 1. Single color and multi-color printing are possible. For web-fed printing presses, double-sided printing can be achieved by changing the conveying route of the substrate or using a flip roller. 2. Printing materials can be widely used in hard materials such as sheet paper, […]

Lire Plus

Inline presse flexo, la machine idéale pour la pré-impression des boîtes de carton ondulé.

With the rapid development of economy and the improvement of living standards, people pay more and more attention to the exquisiteness of packaging. The single-color corrugated carton's transportation and packaging functions of simply protecting products and facilitating storage and transportation are increasingly unable to meet the needs of sales. Therefore, colored corrugated carton packaging is gradually attracting customers' attention. At present, in order to solve the color printing needs of corrugated cartons, pre-printing processing methods have emerged in the printing and processing of corrugated cartons. Today we will introduce a printing machine suitable for pre-printing of corrugated boxes—Inline flexo printing machine. The pre-printing process refers to printing the face paper roll-to-roll before the production of corrugated cardboard. After printing, the web paper is collected into a roll, and then the printed roll paper is sent to the paper worker of the corrugated machine. Position, corrugated cardboard is processed, and then the predetermined color corrugated cardboard boxes are formed through subsequent processes, which is also face paper printing (roll paper)→corrugated cardboard processing → cross-cutting, die-cutting/grooving → box gluing/stacking. What is Inline flexo printing machine? Flexo printing is a recognized green and environmentally friendly printing method in the world. It emits less when printing with ink and causes little environmental pollution, so it is often used in the food printing industry. Flexo printing mainly includes three main models:1. inline flexo printing machine 2. CI flexo press 3. stack flexo press. Among them, the wide web inline flexo printing machine is the ideal model for pre-printing corrugated cartons. Structure of Inline flexo […]

Lire Plus