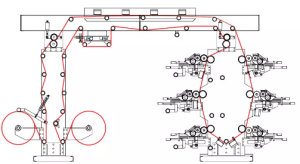

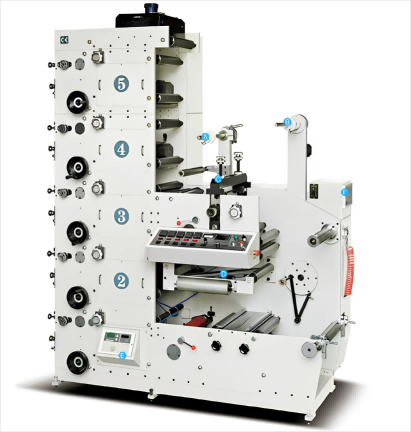

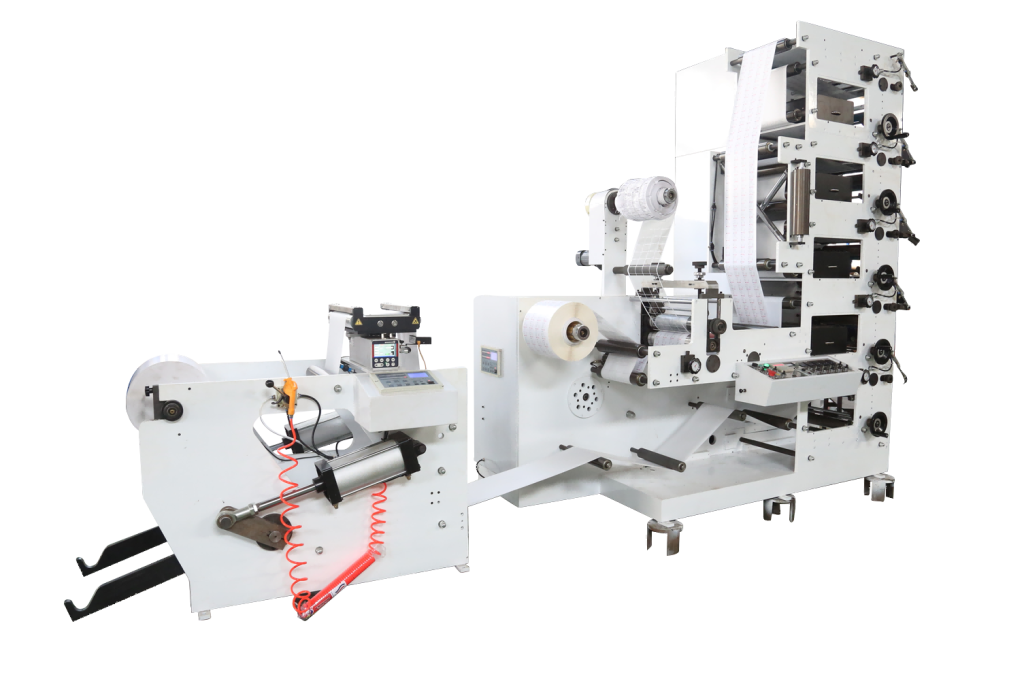

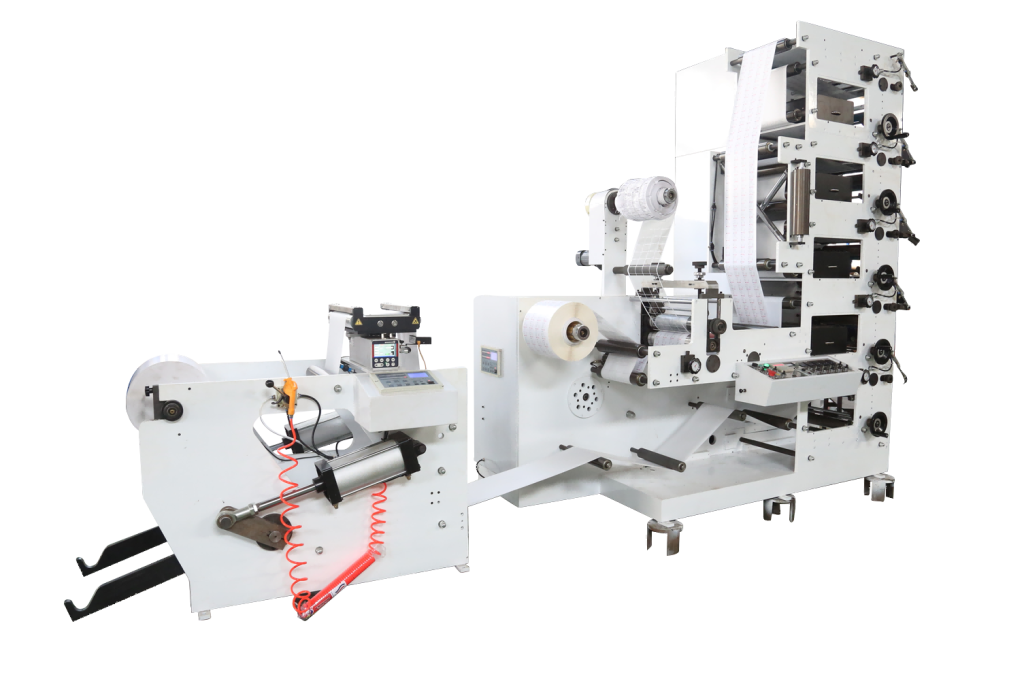

Stack flexo printing machine mainly include 1. Unwind part 2. traction part 3. printing part 4. traction part 5. dry part 6. rewind part.

Advantages and disadvantages

The stackflexographic printing machine has the advantages of small footprint, simple operation, and low price. However, its shortcomings are also quite prominent. The main reason is that the color registration accuracy is lower than the other two models, up to ±0.2mm, and it cannot be used to print high-precision packaging products. Due to the limitations of the machine structure and drying reasons, the speed is significantly lower than the other two types of flexo printing machines.

Summary

The stack flexo printing machine is one of the three types of flexo printing machines. Flexo printing is a recognized green printing method. It emits less when printing with ink and has no pollution to the environment. In addition to conventional paper and PVC, the substrates for flexo printing are Corrugated paper, film and other materials can also be printed. Therefore, flexo printing is widely used in food packaging and pharmaceutical packaging. The stacked machine has a simple structure and a lower price than the other two types. It has the largest market share.

Structure of Flexo printing machine

The printing color groups of the stacked flexographic printing machine are stacked up and down and arranged on one or both sides of the main wall panel of the printing component. Each printing color group is driven by a gear mounted on the main wall panel. During printing, the substrate passes through each printing group in sequence to complete all printing. Each printing color group has an impression cylinder, a plate cylinder and an ink transfer device, and the structure of each printing color group is the same. The laminated flexographic printing machine can print 1 to 8 colors, but most of them are 6 colors. If equipped with a flipping device, it can also print on the front and back sides.

Stack flexo printing machine mainly include 1. Unwind part 2. traction part 3. printing part 4. traction part 5. dry part 6. rewind part.

Advantages and disadvantages

The stackflexographic printing machine has the advantages of small footprint, simple operation, and low price. However, its shortcomings are also quite prominent. The main reason is that the color registration accuracy is lower than the other two models, up to ±0.2mm, and it cannot be used to print high-precision packaging products. Due to the limitations of the machine structure and drying reasons, the speed is significantly lower than the other two types of flexo printing machines.