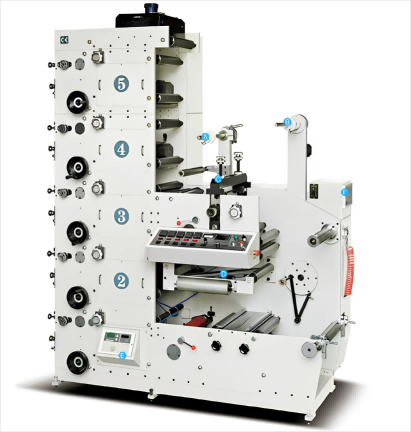

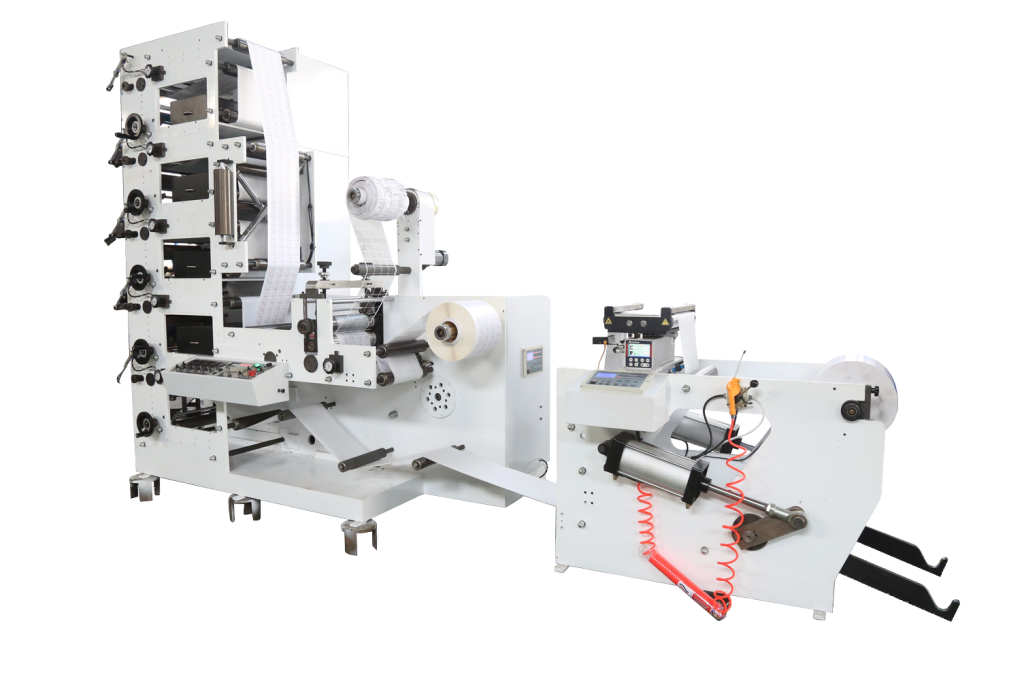

Stack flexo presses, also known as stack flexographic printing machine, are a type of printing press commonly used in the commercial printing industry. These presses are designed to stack printed sheets in an organized manner after the printing process.

High-Volume Printing:

Stacking presses are often employed in high-volume printing operations where large quantities of printed sheets need to be produced efficiently. The stacking feature helps streamline the printing process by organizing and collecting the printed material.

Commercial Printing:

Commercial printing applications, such as the production of brochures, catalogs, magazines, and promotional materials, often utilize stacking presses. These presses allow for the rapid printing and stacking of multiple sheets, ensuring productivity in commercial print shops.

Automated Printing Lines:

Stacking presses are integrated into automated printing lines to enhance efficiency. They work in conjunction with other printing and finishing equipment to create a continuous and automated workflow, reducing manual handling and labor requirements.

Paper and Cardboard Printing:

Stacking presses are suitable for printing on various materials, including paper and cardboard. They can handle different thicknesses and qualities of paper, making them versatile for a range of printing applications.

Book Printing:

In book printing, stacking presses are used to efficiently produce large volumes of printed sheets that will later be assembled into books. The organized stacking of sheets facilitates the subsequent binding and finishing processes.

Variable Printing:

Some stacking presses are designed to handle variable printing, where each sheet may have different content. This is particularly useful in personalized or customized printing applications, such as direct mail campaigns.

Sheet Registration and Alignment:

Stacking presses often include features for precise sheet registration and alignment. This ensures that printed sheets are accurately stacked and ready for further processing or finishing without issues related to misalignment.

Enhanced Productivity:

The stacking function of these presses contributes to increased productivity by minimizing downtime between printing jobs. The organized stacking of sheets allows for efficient handling and retrieval for subsequent processes.

Wide Range of Sheet Sizes:

Stacking presses are designed to accommodate a wide range of sheet sizes. This flexibility makes them suitable for handling various print formats and sizes, contributing to their versatility in the printing industry.

Quality Control:

Stacking presses often incorporate quality control features to ensure that printed sheets meet specified standards. These features may include sensors or vision systems to detect defects or errors in the printed material.